Intelligent Pipe Prefabrication Equipment

-

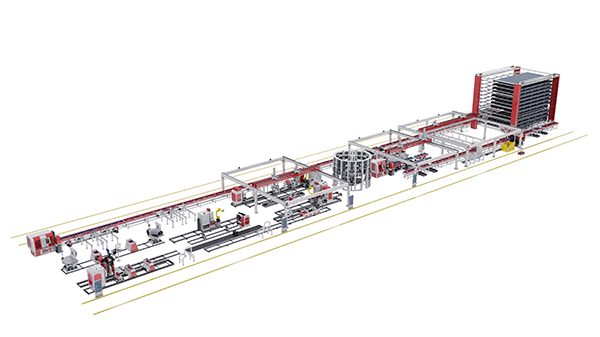

- Prefabricated Pipe Spool Production Line

Prefabricated Pipe Spool Production Line is a complete and integrated system for efficiently manufacturing large quantities of pipe spools to a high standard of quality. The automation and optimized workflow of the line significantly reduces the time it takes to fabricate each pipe spool, enabling faster project completion.

-

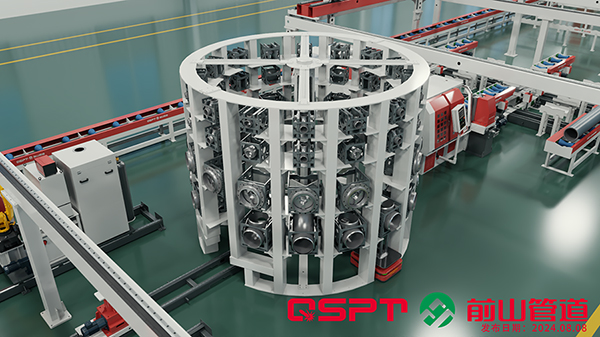

- Automated Pipe Racking System

The intelligent three-dimensional warehouse for pipeline prefabrication consists of two main sections: the intelligent pipe storage warehouse and the intelligent pipe retrieval warehouse. This advanced storage system is specifically designed to enable the smart access, management, and organization of essential materials, including pipes, pipe fittings, and prefabricated pipe sections, ensuring seamless efficiency throughout the pipeline prefabrication process.

-

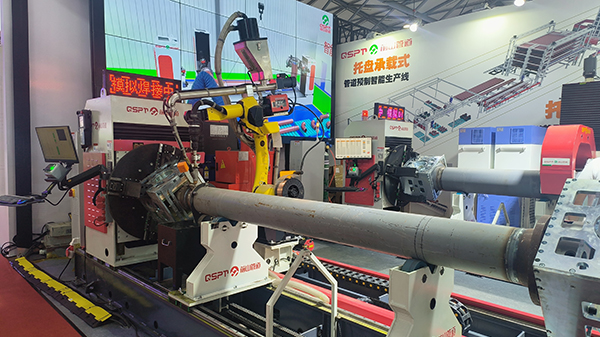

- Submerged Arc Welding System

The intelligent submerged arc welding system is used for enhancing and optimizing the welding process in pipeline prefabrication. It is designed for high-precision submerged arc welding (SAW) operations, improving efficiency, consistency, and welding quality.

-

- Pipe Fit-Up & Welding System

The intelligent pipe fit-up & welding system for pipe spool prefabrication is designed to streamline fit-up and welding operations in the pipeline fabrication process. Its main function is to precisely align the ends or multiple components of pipelines, enabling automated welding that ensures exceptional precision and efficiency in pipeline connections.

-

- Pipe Cutting & Beveling System

The intelligent pipe cutting and beveling system is designed for smart transformation and optimization of pipe cutting and beveling processes.

Semi-intelligent pipe prefabricated production line which is designed with intelligent/QR code scanning to recall the stored program

-

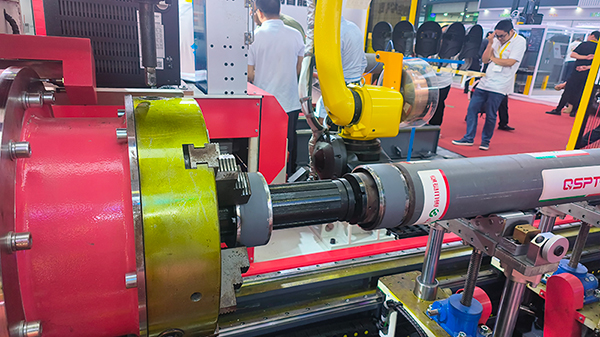

- Pipe Fit-Up & Root Pass Welding System

The pipe fit-up and root pass welding system plays a crucial role in pipe prefabrication and installation. Employing advanced sensors and laser vision technology, the system provides real-time monitoring of pipe diameter, wall thickness, and length. This ensures precise fit-up, resulting in superior welding performance and minimized tolerance.