Pipe Fabrication Welding Equipment

-

- Automatic Welding Machine for Pipe Spool Root Pass Weld (GMAW/GTAW/FCAW)

Welding Line Applicable: Various welding lines of spool pieces such as pipe-pipe, pipe-elbow, pipe-flange, flange-flange and flange-elbow, etc. (a fake pipe transition connection shall be applied if necessary).

-

- Split Type Automatic Pipe Welding Machine (Ordinary Type)

Perfect welder for welding stations in the field

Greatly improved working efficiency

Separated weld drive system and column/boom system

The drive system is mobile along rails

-

- Automatic Pipe Welding Robot

The automatic pipe welding robot is designed with a MIG welder, 6-axis robot, vision-guided system, single-axis welding positioner, pipe support unit, robotic walking rail, electrical control cabinet, welding gun cleaner, etc. Due to the vision-guided system, automatic welding of pipe-pipe intersection and circumferential welding between pipes and fittings can be precisely performed.

-

- Pipe Automatic Welding Machine (FCAW/GMAW)

The pipe automatic welding offers good driving reliability. However, driven by frictional force, it is required to set essential balance weight to offset large bending moment caused by elbows for large diameter pipe, or providing a chain tensioner to improve the reliability of the driving.

-

- Split Type Automatic Pipe Welding Machine (Heavy Duty Type)

Suitable for pipe prefabrication lines

Greatly increased pipe processing efficiency

Separated weld drive system and column/boom system

The drive system is mobile along rails

-

- Automatic Pipe Welding Machine (MIG)Welding Line Applicable: Various butt welding lines of spool pieces such as pipe-pipe, pipe-elbow, pipe-flange, flange-flange and flange-elbow, etc. (a fake pipe transition connection shall be applied if necessary).

-

- Automatic Pipe Welding Machine (SAW)

Pipe Diameter Applicable: DN150-600(φ168-610mm); ~610); DN200-800(φ219-813)

Pipe Wall Thickness Applicable: 6~60MM

Applicable Materials: Carbon steel, alloy steel, stainless steel and cryogenic steel, etc.

-

- Automatic Pipe Welding Machine (GTAW)

The automatic pipe welding offers good driving reliability. However, driven by frictional force, it is required to set essential balance weight to offset large bending moment caused by elbows for large diameter pipe, or providing a chain tensioner to improve the reliability of the driving.

-

- Automatic Piping Welding Machine (FCAW/GMAW, Cantilever)

The automatic piping welding machine offers excellent welding efficiency (200-300 inch/day).

The machine is easy to operate.

The automatic piping welding machine offers excellent surface finishing.

-

- Automatic Piping Welding Machine (SAW, Cantilever)

Adjustment Mode: Manual cross regulator

Control System: A product of our patented technology

Welding Procedure: SAW

Welding Power: OEM products in China (or as per customers' demands)

-

- Automatic Piping Welding Machine (GTAW, Cantilever)

Driving System: Pipe welding positioner is used, clamped pipe by 2 (or 3, 4) jaw chuck and drive it by positioner directly/pipe welding driving machine is used, clamped pipe and drive it by chain directly.

-

- Automatic Portable Piping Welding Machine (FCAW/GMAW)

Most portable and cost-effective type with main functions of the ordinary automatic welding machine; Suitable for automatic welding in the traditional way of prefabrication; two sets of polyurethane coated wheels (two pcs per set, totally four pcs); driven by motor and reducer...

-

- Automatic Piping Welding Machine (SAW, Heavy Wall Thickness)

The automatic piping welding offers good driving reliability (driven with friction; the necessary balance weight shall be provided for the pipe with DN≥600 and which the wall thickness is ≥40 to balance the serious eccentricity resulting from bending).

-

- Automatic Pipe Flange Welding Machine (GTAWTIG)

The automatic pipe flange welding machine offers excellent welding capacity (150-250 inch/day, which is four times higher than manual welding).

The machine is easy to operate.

The automatic pipe flange welding machine offers excellent surface forming.

-

- Automatic Slip-On Flange Welding Machine (FCAW/GMAW)

Pipe Diameter Applicable: DN100-600(φ114-610)/DN100-800(φ114-813)

Pipe Wall Thickness Applicable: 3-30MM

Applicable Materials: Carbon steel, alloy steel, stainless steel and cryogenic steel, etc.

-

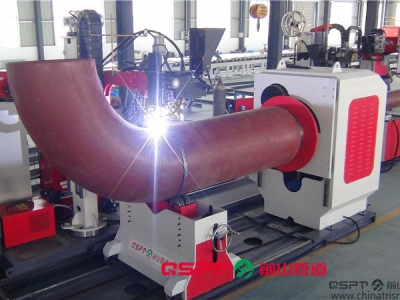

- Welding Elbow Automatic Welding Machine (FCAW/GMAW)

The welding elbow automatic welding machine a welding capacity of 15-30 meters/day(SCH40).

The machine is easy to operate.

The welding elbow automatic welding machine offers excellent surface forming.

-

- Multifunction Automatic Pipe Welding Machine (TIG+MIG+SAW, Cantilever Type)

The multifunction automatic pipe welding machine has a broad application range. It is applicable for cosmetic welding of pipe and pipe fittings with DN diameter not less than 150mm, in various industries.

-

- Multifunction Automatic Pipe Welding Machine (TIG+MIG+SAW, Press Roller Type)

The automatic pipe welding machine makes use of friction force to drive the pipes. When the machine is used to connect a pipe elbow to a pipe with DN diameter no less than 600mm and wall thickness no less than 40mm, a balance weight is necessary so as to avoid eccentricity caused by the heavy weight of the pipe elbow.

-

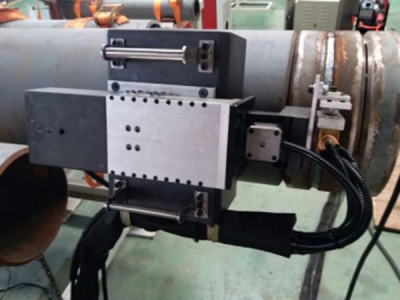

- Automatic Magnetic Pulse Pipeline Welding Machine

The workpiece (pipe) is fixed. Welding trolley around the workpiece rotates to achieve full-position automatic welding of pipeline. Welding process: Automatic magnetic pulse pipeline welding machine uses high-efficiency and low-cost gas to protect welding.