Automatic Pulse Tube Sheet Welding Machine (GTAW/TIG)

Model: PAAWM-80A

Technical Parameters- Welding Source

Model of the Welding Source: Panasonic TIGSTAR400

Type of Power Source: IGBT inversion

Welding Current: 4-315A

Duty Cycle: 315A 60; 244A 100%

Rated Load Voltage: 70V

Rated Power: 9.5 kw

Fluctuation Range of Input Voltage Allows: 380v±10%

Frequency: 50/60Hz - Welding Head

Pipe Diameter: Φ8~Φ80mm (or as per request)

Pipe Wall Thickness: 0.5-6.5mm

Maximum Length of Tube Elongation: 10mm

Maximum Depth of Tube Indentation: 2mm

Feeding Wire Adjustable Angle: ≤45°

Feeding Speed: 0.1~1.5m/min

Dia. of Filler Wire: 0.8mm

Rev Speed of Head: 0.15~6r /min

Welding Speed: 50~150mm/min

Tungsten Adjustable Angle: ≤45°

Positioning Spindle Cooling: Automatic forced cycle water-cooled - Program-controlled System

Welding Current Adjustment Range: 4~315A

Current Rise Time: 0.1~20s

Current Fall Time: 0.1~20s

Pulse Frequency: 0.5~500Hz

Duty Cycle Adjustment Range: 10%~50%

Aspirated Time in Advance: 1~20s

Time Lag Aspirated: 2-20s

Feeding Speed Adjustment Range: 0~1.5m/min

Welding Head Rev Speed Adjustment Range: 0.15~6r/min

Built-in Storage Capacity of 100 Welding Code

Can Partition Paragraph: 1-6 paragraph

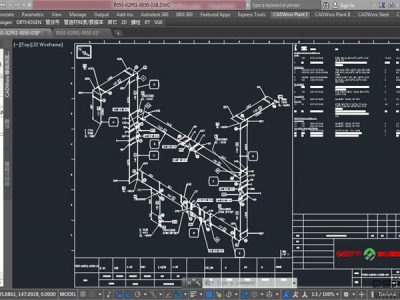

Display: LCD - Gantry and 5D System

Lateral Movement Stroke: 16000mm

Vertical Movement Stroke: 16000mm

Axial Movement Stroke: 300mm

As a professional automatic pulse tube sheet welding machine manufacturer and supplier based in China, we also offer high speed pipe cutting and beveling machine, pipeline end beveling machine, pipe fabrication production line, automatic welding machine for root pass weld, and much more.