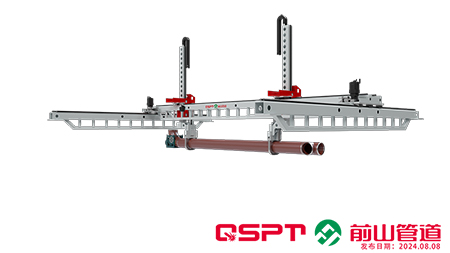

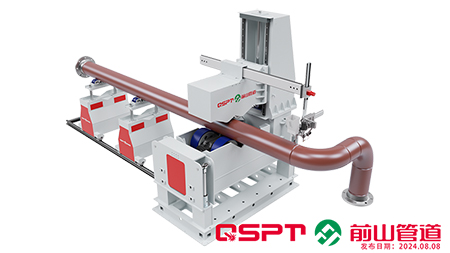

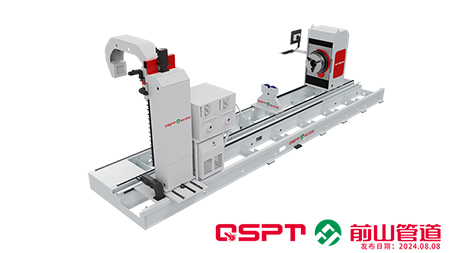

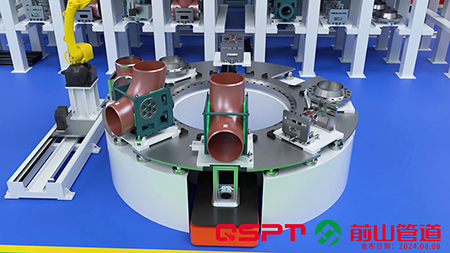

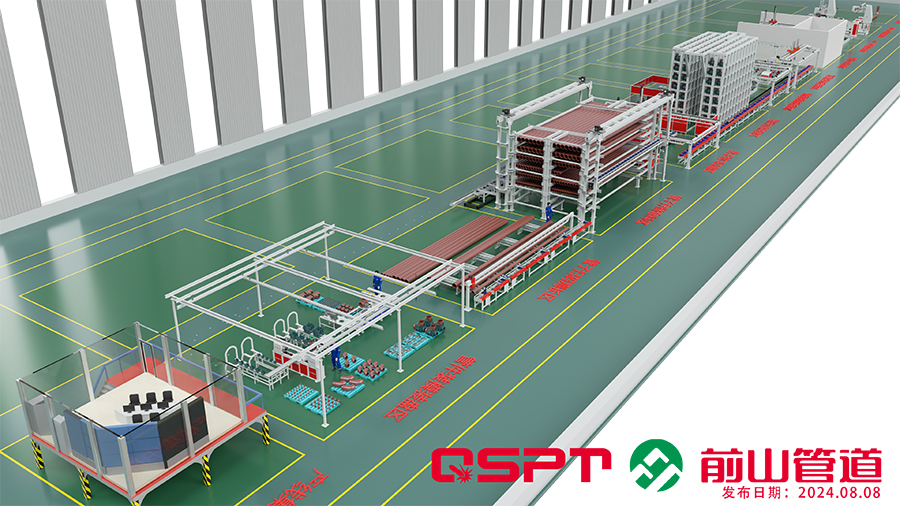

Pallet Carrier Type Prefabricated Pipe Spool Production Line

Intelligent production line for creating pre-fabricated sections of piping system

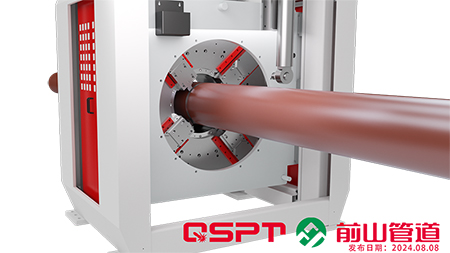

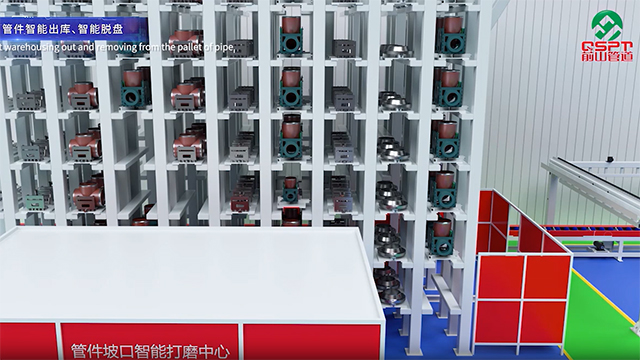

Pallet carrier type prefabricated pipe spool production line fixes flanges, tees, reducers, elbows, and other pipe fittings for efficient assembly and welding, making it ideal for small- to medium-diameter pipe.

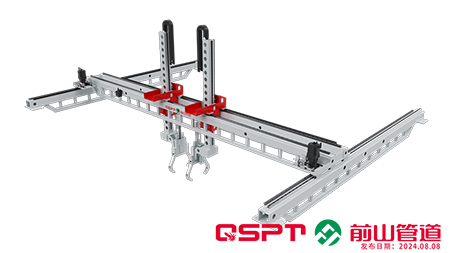

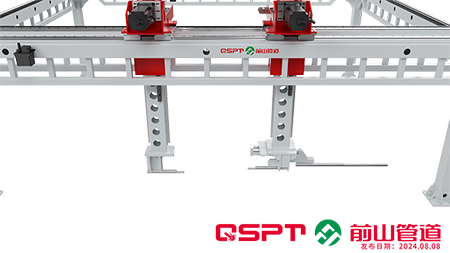

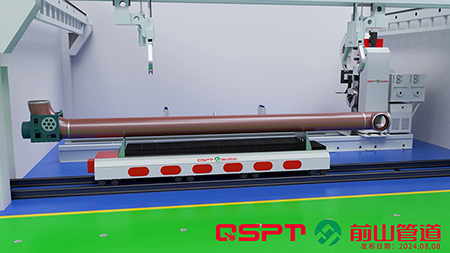

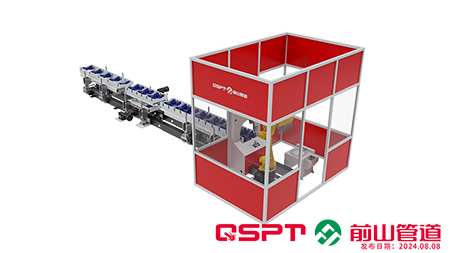

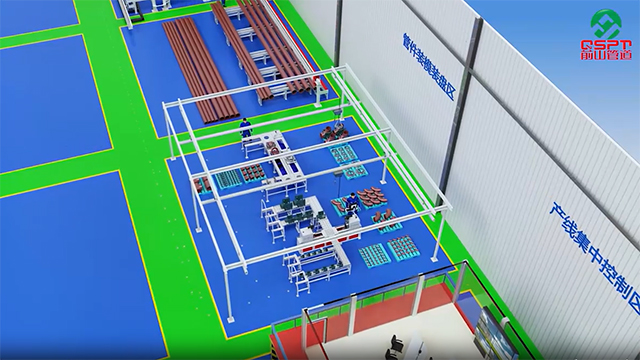

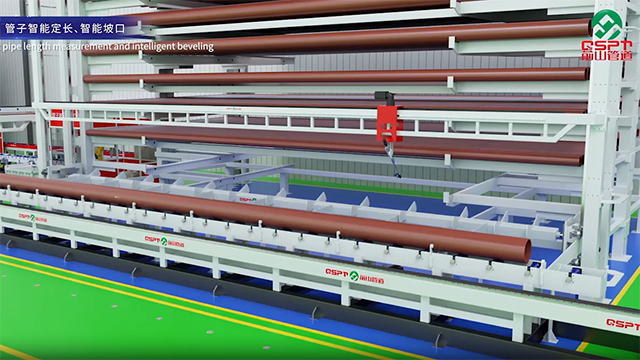

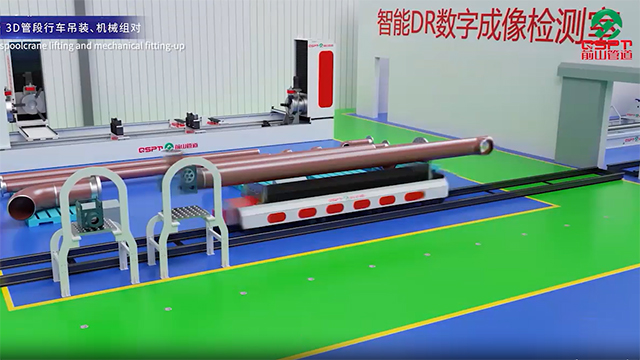

The prefabricated pipe spool production line integrates advanced technologies, including pipe fitting pallet carrier systems, truss manipulator hoisting, laser vision inspection, robotic grinding and welding, AGV (Automated Guided Vehicle) transportation, and digital imaging inspection. Utilizing an intelligent management, control, and monitoring system, this line achieves full automation of the entire pipeline prefabrication process, covering storage, cutting, beveling, fit-up, welding, NDT (Non-Destructive Testing), and transportation, enhancing efficiency, precision, and production quality.

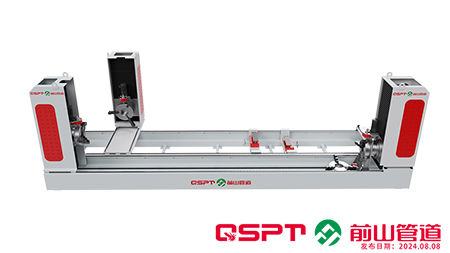

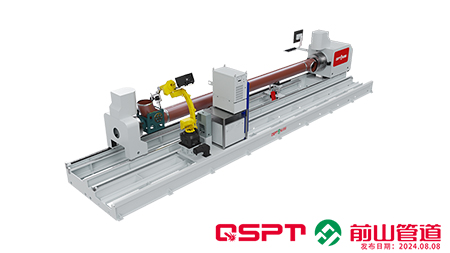

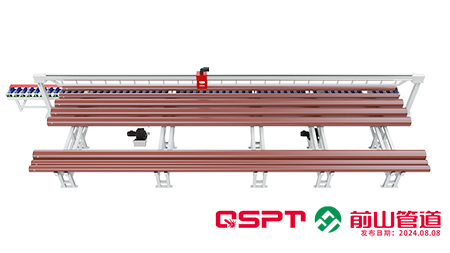

Technical Parameters- Production capacity: 20-150000 inches/month (depending on workshop area and equipment configurations, or as per request)

- Pipe diameter: DN400/DN600/DN800/DN1000/DN1200

- Pipe wall thickness: 3-80mm

- Conveying speed: 2-20m/min

- Beveling speed: ≤5min/two bevels (DN200 SCH40)

- Automatic welding rate: ≥60%

- Prefabrication ratio 50%-80%

- Design software: PDSOFT 3D

- Management software: PDSOFT SPFMS

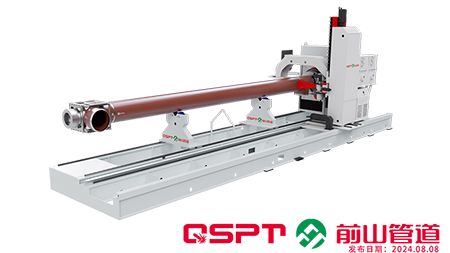

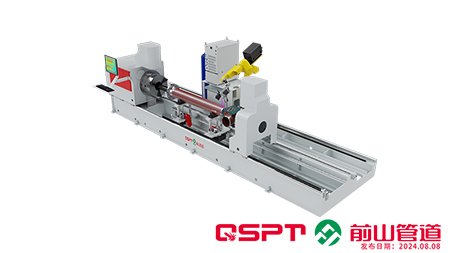

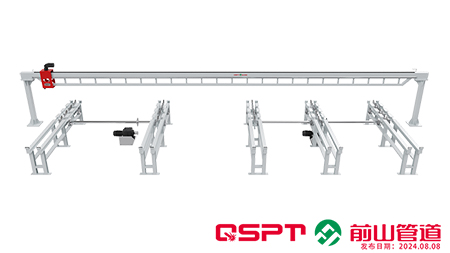

- Petrochemical Industry. Pallet carrier type prefabricated pipe spool production lines efficiently and accurately perform pipeline cutting, beveling, welding, and other processes, ensuring high-quality and safe pipeline prefabrication.

- Power Industry. The power industry has a significant demand for pipeline prefabrication, particularly in power plant construction and transmission projects. The prefabricated pipe spool production line can swiftly adjust production parameters to meet customer requirements, providing customized pipeline prefabrication solutions.

- Power Industry. The prefabricated pipe spool production line enhances production efficiency, reduces manufacturing costs, and improves the overall quality of shipbuilding by streamlining the pipeline fabrication process.

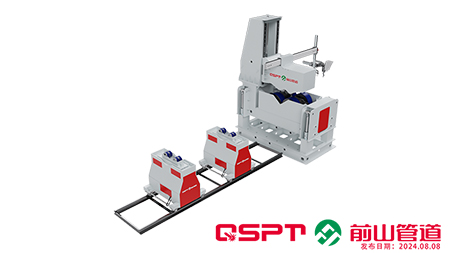

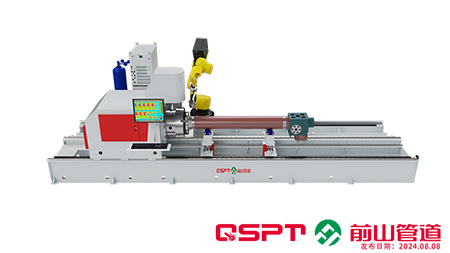

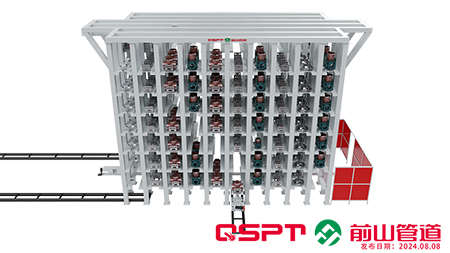

- Intelligent Logistics System. Equipped with an advanced logistics system, including AGV (Automated Guided Vehicle) transportation technology, the production line can automatically move palletized pipes through various processing stages. This ensures seamless workflow integration, minimizes waiting time, and reduces manual intervention.

- Flexible Production Adjustments. The system can swiftly modify production parameters based on specific customer requirements, enabling the efficient production of prefabricated pipeline products that meet precise specifications.

- Versatile Industrial Applications. Designed for factory-based prefabrication of large-scale process pipelines, the pallet-supported intelligent production line caters to the diverse needs of various industries, ensuring adaptability across multiple sectors.