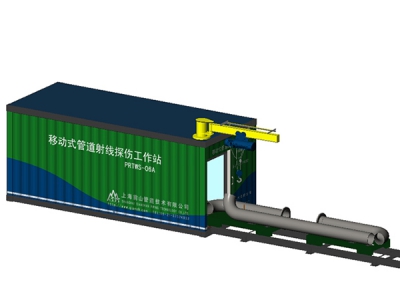

Automatic Piping Welding Workstation (Type-C)

Model: PAWWS-24Cb/PAWWS-24Cc/PAWWS-24Cd

Technical Parameters- Pipe Diameter Applicable: DN50~600 (φ60~610) mm

- Pipe Wall Thickness Applicable: 3-20/3-20/3-60MM

- Applicable Materials: Carbon steel, alloy steel, stainless steel and cryogenic steel

- Welding Line Applicable: Various of butt welding lines for pipe spools such as pipe-pipe, pipe-elbow, pipe-flange, flange-flange and flange-elbow, etc.

- Welding Procedure: FCAW/FCAW/FCAW+SAW (Option or as per request)

- Welding Power: NBC-500/NBC-500/NBC-500+MZ-630 (Option or as per request)

Applications

The automatic piping welding workstation is used for projects with a majority of standard wall thickness pipes and few heavy wall thickness pipes.

- The basic configuration of the automatic piping welding workstation consists of one piece of 6m container made with special retrofit, one set of piping prefabrication automatic welding machine+one piping cantilever automatic welding machine; or one set of piping prefabrication automatic welding machine+one set of automatic portable piping welding machine ; or one set of piping prefabrication automatic welding machine+one set of automatic piping welding machine, and two sets of rail and trolley conveying system, 2 sets of cantilever cranes (option) and two sets of fcaw welding source or two sets of fcaw welding source or one set of fcaw welding source +one set of saw welding source.

- The automatic piping welding workstation has a production efficiency of 450~650 O.D-Inch per day (DN200 SCH40).

- It offers excellent equipment mobility (without limitation of radiation radius when using container as carrier).

As a professional automatic piping welding workstation manufacturer based in China, we not only provide pipe fabrication workstation, but also offer pipe fabrication production line, pipe fabrication welding equipment, pipe fabrication fitting-up equipment, and pipe fabrication beveling equipment.