Automatic Piping Welding Workstation (Type-D)

Model: PAWWS-16Aa/24Aa

Technical Parameters- Pipe Diameter Applicable: DN400/DN600

- Pipe Wall Thickness Applicable: 3-20/3-20/3-20/10-60MM

- Applicable Materials: Carbon steel, alloy steel, stainless steel and cryogenic steel

- Welding Line Applicable: Various of butt welding lines for pipe spools such as pipe-pipe, pipe-elbow, pipe-flange, flange-flange and flange-elbow, etc.

- Welding Procedure: FCAW/FCAW/FCAW/SAW (Option or as per request)

- Welding Power: NBC-500/NBC-500/NBC-500/MZ-630 (Option or as per request)

Applications

The automatic piping welding workstation is used for projects with a majority of standard wall thickness pipes and few heavy wall thickness pipes. It can also be used for projects with a majority of heavy wall thickness pipes and few standard wall thickness pipes (PAWWS-24Dd).

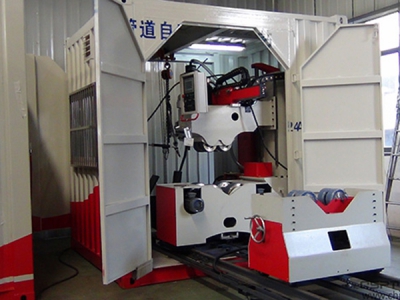

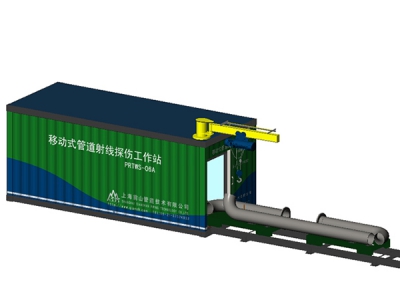

- The basic configuration of the automatic piping welding workstation consists of one piece of 3m container made with special retrofit, one set of piping prefabrication automatic welding machine/piping cantilever automatic welding machine/automatic portable piping welding machine/heavy duty wall thickness piping automatic welding machine, one set of rail and trolley conveying system, one set of cantilever cranes (option) and one set of fcaw welding source/fcaw welding source/fcaw welding source/ saw welding source.

- Production efficiency of the automatic piping welding workstation is 225~350 O.D-Inch per day (DN200 SCH40).

- It offers excellent equipment mobility (without limitation of radiation radius when using container as carrier).

- Specialized field workstation; High welding efficiency and good welding quality; Suitable for automatic welding of all kinds of spool pieces. Equipped with: one specially retrofitted 6M container + one or two Split Type Pipe Automatic Welding Machines.

Qianshan is a primary automatic piping welding workstation manufacturer based in China. Our products include pipe fabrication production line, high speed pipe end beveling machine, pipe automatic welding machine, pipe plasma beveling and cutting machine, pipe prefabrication conveying system, and more.