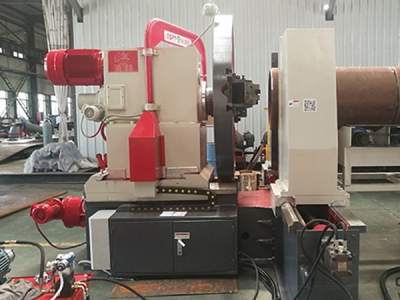

High Speed Pipe End Beveling Machine

Model: EPEBM-24Dc/32Dc/40Dc/48Dc/60Dc

Technical Parameters- Pipe Diameter Applicable: DN600/DN800/DN1000/DN1200/DN1500

- Pipe Wall Thickness Applicable: 4-90mm/6-180MM

- Applicable Materials: Carbon steel, alloy steel, stainless steel and cryogenic steel, etc.

- Bevel Shape: U, X, V and Double V

- Cutting Direction: Radial automatic differential cutting feed or axial semi-automatic motor cutting feed; radial automatic differential cutting feed or axial automatic motor cutting feed

- Retracting Direction: radial automatic motor retracting or axial semi-automatic motor retracting; radial automatic differential cutting feed or axial automatic motor cutting feed

- Driven by: Motor

- Clamping System: Work piece is clamped by (screw rod) hydraulic cylinder

- Bracket System: Screw lifting adjustable

- Rev of the Principal Axis: 3shifts (67-123rpm)/9 shifts (34-304rpm)

- Axial Displacement: 80mm(principle axis) 100mm(machine head)/150mm (principal axis), 300mm (machine head)

- Widthwise Displacement: ±50mm/±100mm

- Bevel Angle of Tool Rest: 0°~37.5°

- Control System: Gear shift for main shaft, VF speed change for axial direction movement and manual control; gear shift for main shaft, VF speed change for axial direction movement and PLC control

- Mechanical Aligning: At the end of beveling machine conveying system it can be equipped with lifting device if necessary to automatically adjust the center elevation of the pipe to bevel pipes with different diameters

- Conveying System: Can be equipped for roller conveying system if necessary

Applications

The high speed pipe ending beveling machine is used for machining the U or V shape bevels for pipes with heavy wall thickness.

- The high speed pipe end beveling has a beveling speed of ≤5Min /pipe bevel (DN200 SCH40).

- It offers bevel cutting of: cutting a pipe with other equipment such as band saw and then machining each bevel.

- Bevel quality is very good.

- Bevel shape: V, double V and U; applicable for the radial or axial beveling of STD wall pipe and radial beveling of thick-wall pipes; Centering-clamp from top and bottom synchronously with hydraulic motor + screw rod; radial differential feed, motorized discharge or feed/discharge controlled by axial common motor; standard numerical control blade without coolant.

We are a professional high speed pipe end beveling machine manufacturer based in China. We provide pipe fabrication beveling equipment, pipe fabrication welding equipment, pipe fabrication conveying equipment, pipe fabrication production line, pipe fabrication cutting equipment, and much more.

Pipe Prefabrication Machine

Inquiry