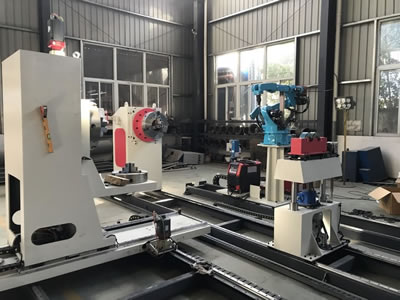

Automatic Pipe Welding Robot

Model: PPRWC-24Aa

Technical Parameters- Power Supply: 380VAC 50Hz

- Dimensions: 8000 (L) x 3000(W) x 2000 (H) mm

- Operation Mode: Control handle for mouse/keyboard/industrial switch/robot

- Working Environment: 0℃-45℃

- IP Rating: IP54

- Welding Precision: 0.5mm

The automatic pipe welding robot is designed with a MIG welder, 6-axis robot, vision-guided system, single-axis welding positioner, pipe support unit, robotic walking rail, electrical control cabinet, welding gun cleaner, etc. Due to the vision-guided system, automatic welding of pipe-pipe intersection and circumferential welding between pipes and fittings can be precisely performed.

Features- No vibration will be generated during the welding process, and a steady, consistent motion is always maintained, which delivers high quality welds with a good appearance.

- The welding automation equipment ensures safe operation, and ergonomic comfort. It greatly lessens the need for operator’s exposure to environments with loud noise or high temperature.

- Welding automation greatly improves welding efficiency, which is not influenced by the operator’s skill.

| Item | Model | Qty. | Details |

| Welding robot | ZGRB06-2000-MK | 1pc | 6-axis robot installed in a regular way |

| Robot control cabinet | ZGRC0920-A3 | 1pc | Moves with the robot on the rail |

| Robotic walking rail | 1 set | Welding robot moves on the rail featuring a structure of linear guide with gear rack. This provides precise robot motion, with an effective stroke of 6m. | |

| Three-jaw welding chuck | 2t | 1 set | 3-jaw self-centering pipe weld chuck, suitable for pipes with length of 300-600mm |

| Pipe cart | 2pcs | manual moving and lifting | |

| Rail for supporting carts | 1 set | 6m in length | |

| Welding torch holder | 1 set | Keeps welding torch steady during the MIG welding process | |

| MIG welding power source | MIG500 | 1 set | 500A MIG welding power source; MIG welder specially equipped for the welding robot; welding torch and wire feeder delivered with the MIG welder; |

| Laser seam tracking welding sensor | 1 set | Specially designed sensor for welding with vision is used for tracking during pipe-to-pipe intersection line welding and circumferential welding. | |

| Electrical control cabinet | 1 set | Features HMI interface for welding, facilitating welding process setting; settings can be stored for easily recalling job recipes at any time; | |

| Handheld robotic teach pendant | 1 set | Standardized robot control handle | |

| Cables | 1 set | Used for all connections in the welding robot | |

| Spare parts delivered with the equipment | 1 batch | Tools included | |

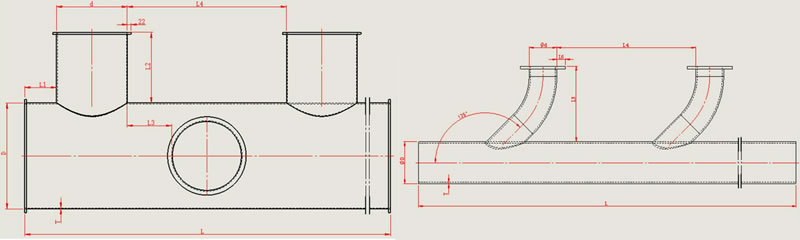

| Item | Code | Parameter |

| Header Pipe O.D. | D | ⌀ 159-630mm |

| Branch Pipe I.D. | d | ⌀ 108-426mm |

| Pipe Wall Thickness | T | 3-14mm |

| Branch Connection Distance from Joint Seam | L1 | ≥180mm |

| Straight Branch Pipe Height | L2 | 70-480 mm |

| Branch Connection Distance | L3 | ≥250mm |

| Branch Connection Distance | L4 | ≥900mm |