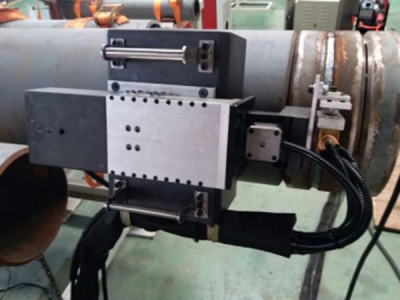

Multifunction Automatic Pipe Welding Machine (TIG+MIG+SAW, Press Roller Type)

Model: PPAWM-24Ab; PPAWM-32Ab

Technical Parameters- Pipe diameter applicable: DN100-600 (φ114-610mm); DN200-800 (φ219-813mm) or customizable

- Pipe wall thickness applicable: 3-60 mm

- Materials applicable: carbon steel, alloy steel, stainless steel and cryogenic steel

- Welds applicable: the machine supports pipe-pipe, pipe-elbow, pipe-flange, flange-flange and flange-elbow welding, etc.

- Pipe driving system: Two row of metal with rubber compound idler wheel driven by motor

- Clamping system: clamping by with cross arm clamping mechanism

- Bracket system: it is a separated trolley system for the welding machine, and can be adjusted along the track according to the length of the pipe

- Counterweight System: No

- Speed-regulation Mode: VF stepless speed control

- Control system: PLC control with touch screen, a product of our patented technology

- Welding procedure: TIG+MIG+SAW for spool piece automatic root pass, fill in & final welding at the same station

- Welding Power: With Lincoln Welding Power Source (or as per customers' demands)

- The multifunctional pipe welding machine can be utilized in a production line, and offers a broad range of applications. It is used in various industries for pipe welding.

- Welding Efficiency: Excellent (250-500 inch/day, which is 4 times higher than the manual welding)

- The equipment is easy for operation. Even a new user can learn how to use it in a short period of time.

- Keeping the welding gun at the optimum position all the time, the welding equipment offers good welding surface quality, and the minimum welding qualification rate is up to 98%. Skilled operators require no re-work at all.

- The automatic pipe welding machine makes use of friction force to drive the pipes. When the machine is used to connect a pipe elbow to a pipe with DN diameter no less than 600mm and wall thickness no less than 40mm, a balance weight is necessary so as to avoid eccentricity caused by the heavy weight of the pipe elbow.