Automatic Magnetic Pulse Pipeline Welding Machine

Parameters- Product type: PAAWM-00Aa

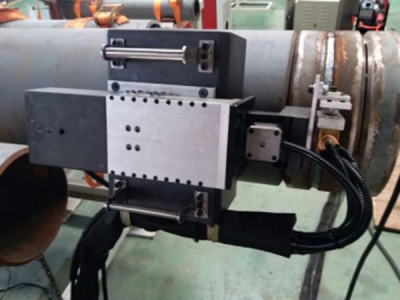

Automatic magnetic pulse pipeline welding machine is composed of power supply, wire feeding system, magnetic welding trolley and welding control system, etc. - Applicable pipe diameter: ≥DN100

Pipe thickness: 4-30

Applicable materials: CS, AS, SS and Cryogenic Steel

Applicable welding joint: Various pipe butt welding joint, such as pipe-pipe, pipe-elbow, pipe-flange, etc. . - Magnetic welding trolley

Driving wheel: Magnetic wheel

Wheel set suction: 》50KG

Driving system: DC servo motor drive

Speed: 50-750MM/MIN, stepless speed control

Rotation accuracy: Rotating a cycle on the DN150-DN400 seamless tube with a center deviation less than 0.5MM

Driving impulse: When rotating downward on the seamless pipe, the driving impulse is less than 0.5mm.

Adjustment system: As our patented product, welding torch stepper motor is used to adjust the position to right and left, up and down.

Oscillating system:As our patented product, welding torch stepper motor adjusts the oscillation to right or left.

- The workpiece (pipe) is fixed. Welding trolley around the workpiece rotates to achieve full-position automatic welding of pipeline. Welding process: Automatic magnetic pulse pipeline welding machine uses high-efficiency and low-cost gas to protect welding.

- Features: It is suitable for filling & final welding of fixed weld for long distance pipeline construction or site installation; carbon steel pipeline welding require no guide rail, the magnetic wheel automatically adsorbs and crawls on the pipeline; trolley with stepless rotational speed control; the welding torch can swing in the axial direction of pipe; the welding torch can be adjusted in angle axially along the pipe; the welding torch can be adjusted in angle axially perpendicular to the pipe; the welding torch can be adjusted radially up and down along the pipe; standard configuration: HiArcM500A welding power supply; solid welding wire + mixed gas & downhill welding, flux-cored wire + mixed gas & uphill welding.