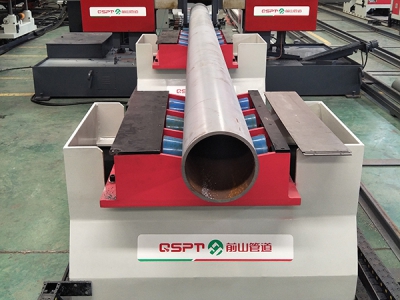

Pipe Conveying System for Cutting Band Saw Machine

Model: PLRCS-16Aa/24Aa/32Aa/40Aa

Technical Parameters- Pipe Diameter Applicable: DN400/DN600/DN800/DN1000

- Conveying Length: Feed in end: ≥1,000MM; Feed out end: ≥500MM

- Line Length: 7.5M at feed in end and 7.5M at feed out end (or depending on customers' requirements)

- Line Height: 800MM

- Material of the Roller Bench: Carbon steel with blue treated surface (coated with rubber if necessary)

- Conveying Speed: 2~20M/Min

- Speed Adjustment: Manual/VF stepless speed adjustment

- Control System: Manual(A1)/PLC control, shared with the pipe cutting length-measuring system (or depending on the situation) (A2)

- The pipe conveying system for cutting band saw machine conveys the pipe automatically or manually when the band saw cuts it and the pipe can be removed from the machine with a turnover mechanism if necessary.

- It increases the automatization level in the pipe fabricating plant and decreases the hazards during hoisting.

- Specially designed conveying system for Pipe Cutting Band Saw Machine; V type polyurethane rollers same as the internal conveying of the pipe cutting band saw machine to ensure the alignment of pipes in all directions; VF stepless speed control, manual control on console (wireless remote control for option).

As a China-based pipe fabrication conveying equipment manufacturer, Qianshan offers pipe conveying system for cutting band saw machine, pipe fabrication production line, high speed pipe end beveling machine, automatic piping welding machine, and much more.